The implementation of robotics in manufacturing is possibly the best thing to happen to the industry since the invention of the assembly line. Robot integration in the manufacturing and machining process improves efficiency and safety, and significantly increases revenue thanks to its groundbreaking speed and accuracy. The future of automation equipment is in robotics.

The latest robotic equipment is extremely accurate, versatile, productive, and can work continuously if well maintained. Although these machines are now closer to approximating the human touch than ever before, human influence will always be necessary for their programming and guidance.

That’s why Ahaus has a team of applications and controls engineers who understand the importance of robotics in the custom automation equipment world, and know how to custom design robots intended for full integration to the exact specifications of our customers’ machining and manufacturing processes. Ahaus engineers work with our customers as partners, and get to the core of every build to determine the best methods of improvement.

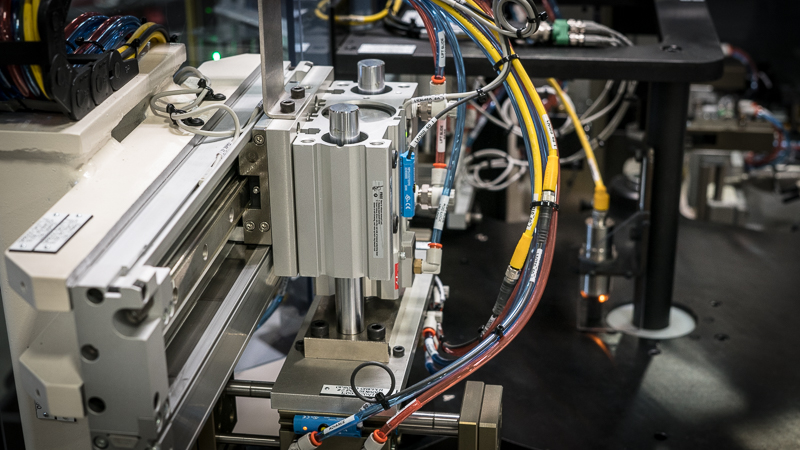

The robotic equipment we have today is remarkably advanced. Through the use of force and torque sensors and “machine vision” technology, the latest robotic systems possess the abilities to identify tasks and precisely orient into position and apply the correct amount of force as it navigates through the work. Robotic integration via intricate programming and powerful computer control systems enable these machines to perform “intelligently,” thereby minimizing the need for human intervention, leaving the real problem solving and innovation to the human experts.