We’ve come quite a long way since Henry Ford first introduced the assembly line in the early part of the 20th century. Even in their wildest dreams, Mr. Ford and his counterparts would have found it difficult to imagine the exponential advances in technology from their time to ours.

The Automation Revolution

The original intent behind the establishment of the assembly line was to increase productivity while decreasing the time and number of workers it took to manufacture a product. To accomplish this, particular tasks were compartmentalized and meticulously timed. New tools and equipment that were more effective such as conveyor belts were rolled out. In no time, this proved to be a much more cost-effective and efficient alternative to previous production methods.

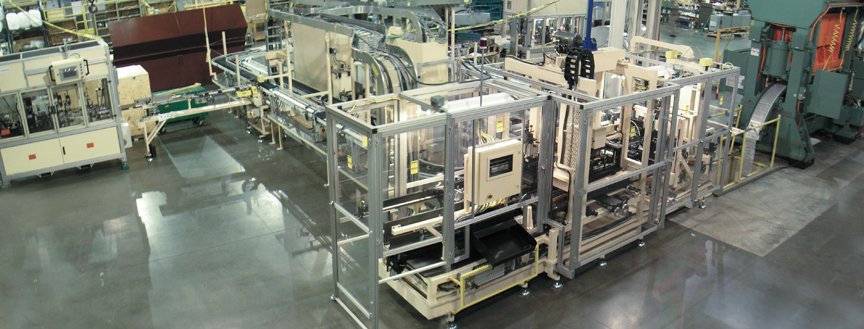

Although the basic philosophy and principles behind the assembly line still hold true, the machinery and methods have changed drastically. The muscle of a once large and relatively unskilled labor force has been replaced by special machines and assembly equipment that require more brains than brawn to operate.

Robotic systems and other automation equipment are now used to manipulate materials and process parts. Combined with 3D computer designs and custom hydraulic workholding fixtures, automated systems not only optimize efficiencies within the manufacturing process, but also facilitate a level of consistency or “repeatability” in production that has never before been achieved.

The concept of integrating computers and machines may at one time have only been espoused within the pages of a science fiction novel. But it has become a reality in the industrial automation equipment of today, which has revolutionized production processes in speed, convenience and accuracy.