Finite Element Analysis (FEA) has long been a cornerstone in engineering, enabling precise simulations that predict how products, components, and systems will perform under various conditions. While FEA has been around for decades, it continues to evolve and is more valuable to engineers than ever. At Ahaus Tool and Engineering, we leverage FEA to ensure our designs meet the highest standards of reliability and efficiency.

Enhancing Design Precision

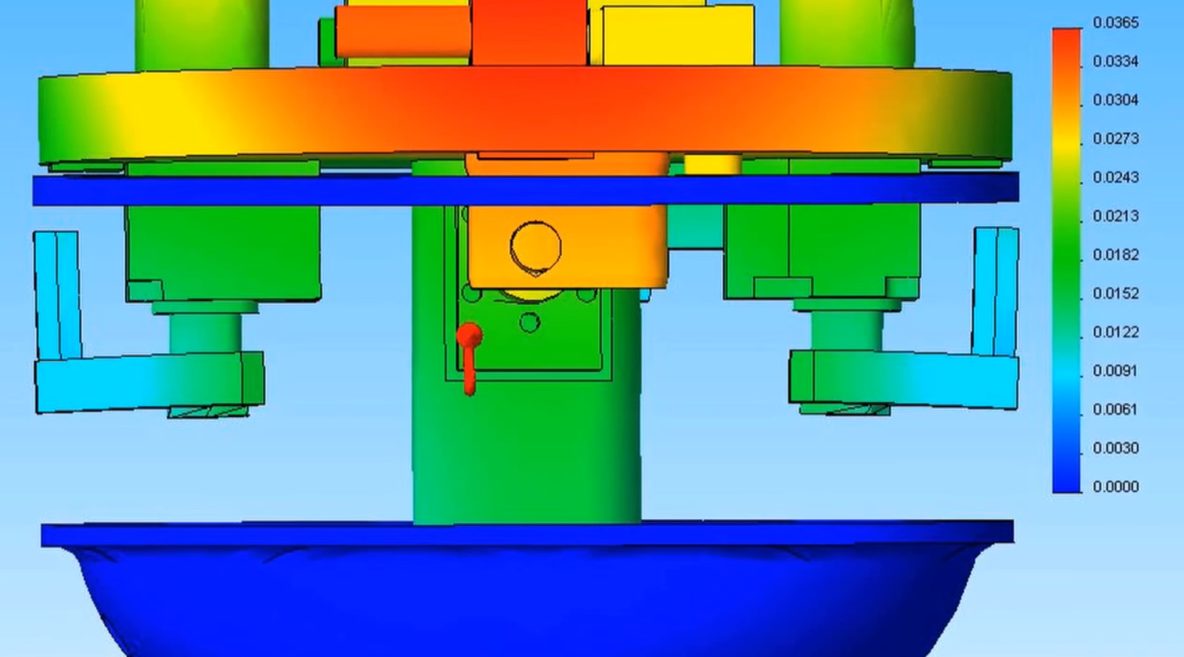

During the design phase, our engineers employ FEA to conduct comprehensive deflection and stress analyses. This process allows us to assess whether a proposed part can withstand operational demands and function as intended. By simulating real-world scenarios, we can identify potential weaknesses early, reducing the need for costly revisions later in the development cycle.

Applications Across Our Services

FEA’s versatility makes it invaluable across various aspects of our work:

- Workholding Solutions: We utilize FEA to evaluate clamp designs, ensuring they apply appropriate pressure without compromising the integrity of the workpiece. This analysis verifies that our fixtures maintain accuracy and consistency, enhancing productivity.

- Rotational Dynamics: For components subjected to rotational forces, FEA helps us determine if they can endure specified speeds without failure. This insight is crucial for optimizing

- performance and ensuring safety in applications involving high-speed rotations.

- Assembly and Specialty Equipment: When designing complex machinery, we analyze the structural integrity of bases and frames to confirm they can support operational loads. This ensures the longevity and reliability of the equipment we deliver.

Advancements in FEA Technology

The field of FEA is continually evolving, with recent advancements enhancing its capabilities:

- Integration with Artificial Intelligence: The fusion of FEA with AI techniques is revolutionizing the field. AI algorithms assist in automating various aspects of the analysis process, including mesh generation, optimization, and result interpretation, thereby enhancing efficiency and accuracy.

- High-Performance Computing: The development of high-performance finite element methods has led to more efficient and accurate simulations, enabling the analysis of complex systems that were previously computationally prohibitive.

Delivering Proven Performance

By integrating FEA into our design process, we provide our clients with products and components that are not only optimized for performance but also validated for reliability. This rigorous analysis eliminates guesswork, allowing us to offer precise specifications for operational parameters such as spin speeds and pressure levels.

Incorporating comprehensive finite element analysis ensures that the machines and parts we design perform their intended functions efficiently and dependably. For more information about the applications of FEA, contact us today.