The Ahaus Workholding Legacy:

5 Keys to CNC Workholding Fixtures That Last

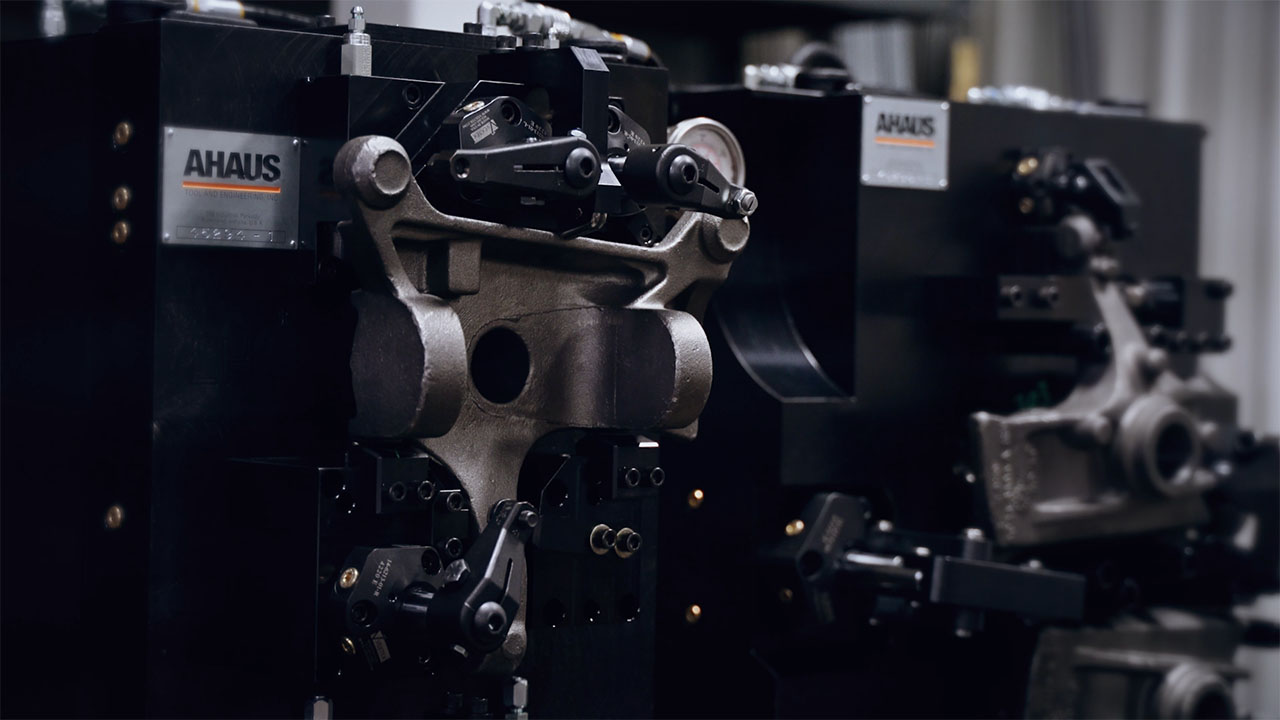

While there are dozens of ways to build a workholding fixtures department inside a traditional tool and die shop, in the mid-1990s Ahaus found a formula that has grown this segment of our business exponentially. The steps we have taken to invest in this portion of our business have resulted in a small, highly skilled team who build, runoff, and install over 200 fixtures each year. Here’s how we make it happen:

1. Custom workholding fixtures fit the strengths of our company and workforce.

Back in the mid-1990s we were producing workholding fixtures for a partner company. As company president Kevin Ahaus remembers, “We realized all at once: This is a good market! There are a lot of people out there with CNC – or computer numerical control, basically machine automated – production equipment who need multiple fixtures for those machines. We can provide that for them, because we have an engineering department that can design those essential fixtures. Then we can take them out to our floor and build them, perform whatever custom work is needed on them, check to make sure they are correct, and then offer them to the market at an appropriately affordable rate.”

From there, custom workholding became part of the fabric of Ahaus to the point where it is one of our core service offerings. Today, we have an entire department that focuses on custom workholding, specializing in workholding fixtures needed by companies that span industries from automotive to medical.

As it turned out, Ahaus entered the custom workholding business at precisely the right time. Just as we were discovering the exciting potential for growth in workholding, other companies began catching on to the efficiency and reliability of CNC machining.

“It was definitely at that time when our company entered the field full steam ahead that I would consider the modern beginning of custom workholding,” Kevin Ahaus says. “Everything we were doing was repeatable in an extremely efficient, extremely precise way. And then the volume of work went up significantly for us and throughout the custom workholding market.”

2. We consider you a member of our team.

Beyond the mechanical, technical, and economic elements of workholding fixtures at Ahaus, there is a customer relationship component that we value just as much. As a customer, you become a collaborative partner with our team at Ahaus in the design and build process. Our workholding projects require fundamentally unique designs that account for countless variables in complex systems with a range of hands-on human involvement and robotic integration. We know our results are as much a factor of our approach to collaboration as they are to our commitment to quality and reliability.

We are in essence not only making something for you, but with you.

“We’re passionate about what we do with custom workholding, because it’s a good industry that fits what we do at the company well,” Kevin Ahaus explains. “We’re making specialty, one-of-a-kind stuff that you simply can’t buy off the shelf. And that’s what our company loves to do and has become so adept at over the last few decades of being in this business.”

That is why we went into custom workholding in the first place. It was a perfect fit from a design, engineering, and fabrication perspective. But it is our people and our dedication to client relationships that make us the ideal choice for businesses with custom workholding fixtures needs.

After the early years of learning and experiencing everything that custom workholding could become, we began to develop an expertise that made our team truly exceptional in the industry. Before long, we were leading the way in what was possible in custom workholding. Pair that with a dedicated workholding project engineer who communicates with the customer through every step of the process, and you have a winning combination.

And, make no mistake, the custom workholding industry is on the rise.

Need an Expert?

Need the Proof?

3. We provide our customers “the entire package”.

When Ahaus first started in the sector back in the 1990s, there were only a few companies delving into what we were doing. Thirty years later, there are now at least fifty such companies around the country trying to do what Ahaus does with custom workholding fixtures.

What makes Ahaus stand out as is that it is not merely the ability to design and build these fixtures through custom workholding. It is about having, as Kevin Ahaus puts it, “the entire package” when it comes to custom design, build, and runoff capability. This is actually what makes the custom workholding sector a very fragmented industry: there are so many different vertical layers to it.

That means that you may have a dozen tool shops in your area that are capable of some elements of custom workholding but perhaps not quite so adept at others. Because of the need for that “entire package” of capabilities and knowledge expertise, there remains only a few competitors that can deliver at the scale required by our clients. And we are confident that Ahaus remains the best and most comprehensive choice, nationwide.

“There are very good companies out there doing what we do,” Kevin Ahaus continues. “But we’ve visibly set ourselves apart from the pack of ‘everyday tool shop’ that purport to do it.”

So much of what sets us apart is our people and our history of trailblazing in the field of workholding fixtures since its inception. Every part of the automation and custom workholding process, from development and programming to operation and production, requires capable people. Our collective wisdom that we continue to cultivate and pass to the next generation is an essential key to our role as innovators going forward. The knowledge and experience that comes with machining fixtures and programming these specialized tools is invaluable. Which is why we’re so proud of our comprehensive in-house apprenticeship program designed for our next generation of experts.

We believe that you can learn to run a modern machine tool relatively easily and can learn how to handle all of the coding over the course of several weeks or months. But, if you’ve never cranked a handle and cut a piece of metal with a hand-operated machine tool, you won’t know what it feels like.

And knowing how it feels and how it really works beyond the automated/CNC elements of the machining tool is why we always make sure to train our apprentices with actual hand-operated tools, hand-drilling operations, and hand-grinding operations. So that when they do get into the computerized/automated/CNC parts of their training, they will know the distinctive sounds, smells, and – yes – feels of the cut in order to more quickly assess if there is an issue that requires attention. These seemingly small details are all part of the process of developing the most innovative and skilled team in the custom workholding industry.

4. We are machinists and designers

Ahaus brings together the best of both worlds: the most cutting-edge software and hardware and CNC machine tools combined with the most highly trained human operators and the well-earned knowledge that we’re proud to continue fostering through our apprenticeship program.

Our fourth-generation president, Kevin Ahaus says, “At Ahaus, we’re machinists as well as designers. Which means that when we’re looking at a project, we’re not guessing at determining what will take to complete it properly and within the exact specifications of what our client partners require.”

Having that experience translates into a different knowledge than some other companies because we’re hands-on. It helps us translate back and forth what’s going to happen next on the floor during our machining day-to-day operations. It’s a good relationship between CNC machining and custom workholding.”

At Ahaus, we understand what it means to machine something, because we do it every day. We’ve designed and built nearly 6,000 custom workholding projects since the mid-1990s, and we get better every day.

To find out how Ahaus can work with you on your custom workholding needs, contact one of our Sales Engineers here: