When we at Ahaus Tool & Engineering describe workholding, what exactly are we talking about? The technical meaning is the “design and build of any device used to safely support or secure a workpiece for … Read More

How to Get a College Education and a Tool and Die Apprenticeship at the Same Time

Lots of companies are hiring right now. You see the “Now Hiring” signs in front of just about every business these days, from retail stores to restaurants to service centers. Many places are offering higher … Read More

How useful is machine vision?

As Artificial Intelligence (AI) and machine learning continue to evolve, the impact these technologies have on the manufacturing industry, particularly automation, also grows. This growth presents many opportunities for innovative solutions to common automation challenges. … Read More

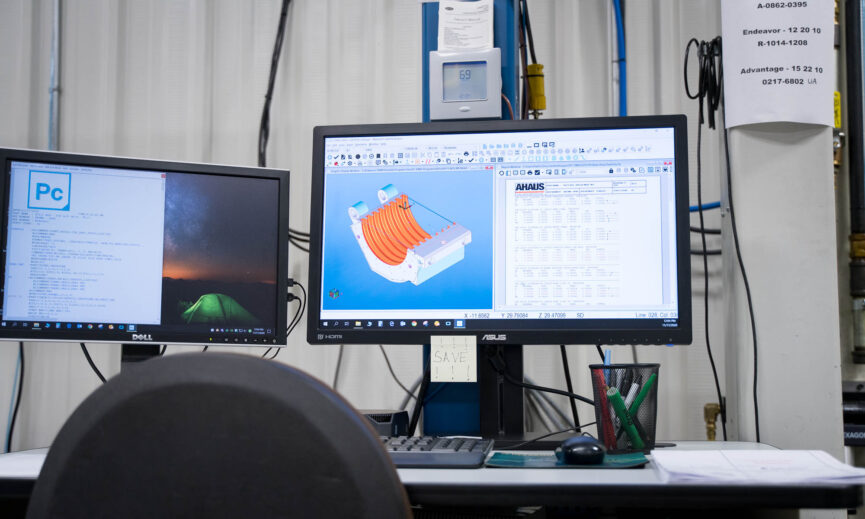

What can custom machining do for my business?

Early versions of CNC (computer numerical control) machining date back to the 1940s and 50s. But this technology, which gives machining professionals greater precision and efficiency compared to manual controls and patterns, really took off … Read More

How do automation and ergonomics help employee safety?

Along with customer satisfaction, the highest priority for any company should be a dedication to safe and comfortable work conditions for its staff. In fact, it’s nearly impossible to achieve the highest levels of customer … Read More

Customers as Partners: Simultaneous Engineering and Collaborative Thinking

Unique, Custom Projects Require Custom Workholding At Ahaus, our vision is to be the most highly sought-after partner to create quality products, life changing experiences, and a sense of community because people trust and value … Read More

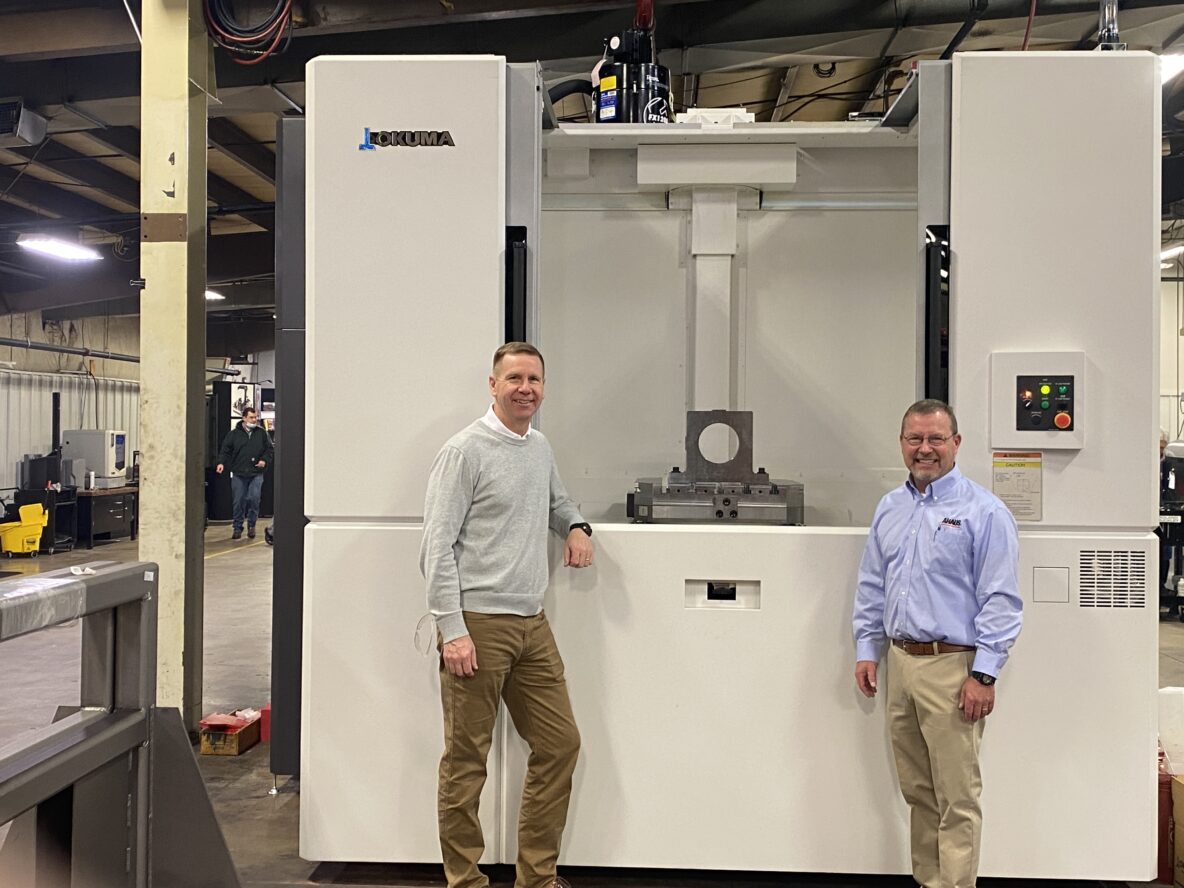

Ahaus Receives Tax Abatement

As we continue to prepare for our future, Ahaus is proud to announce a recent tax abatement. This will allow for the purchase of two machines to continue the current pattern of growth. President Kevin … Read More

Custom Manufacturing Equipment Built From Lasting Customer Relationships

One of the strengths of Ahaus is our long-standing customer relationships. Our engineers and designers work in tandem with our customers to build the best precision machining fixtures, power generation and automation equipment we can. … Read More

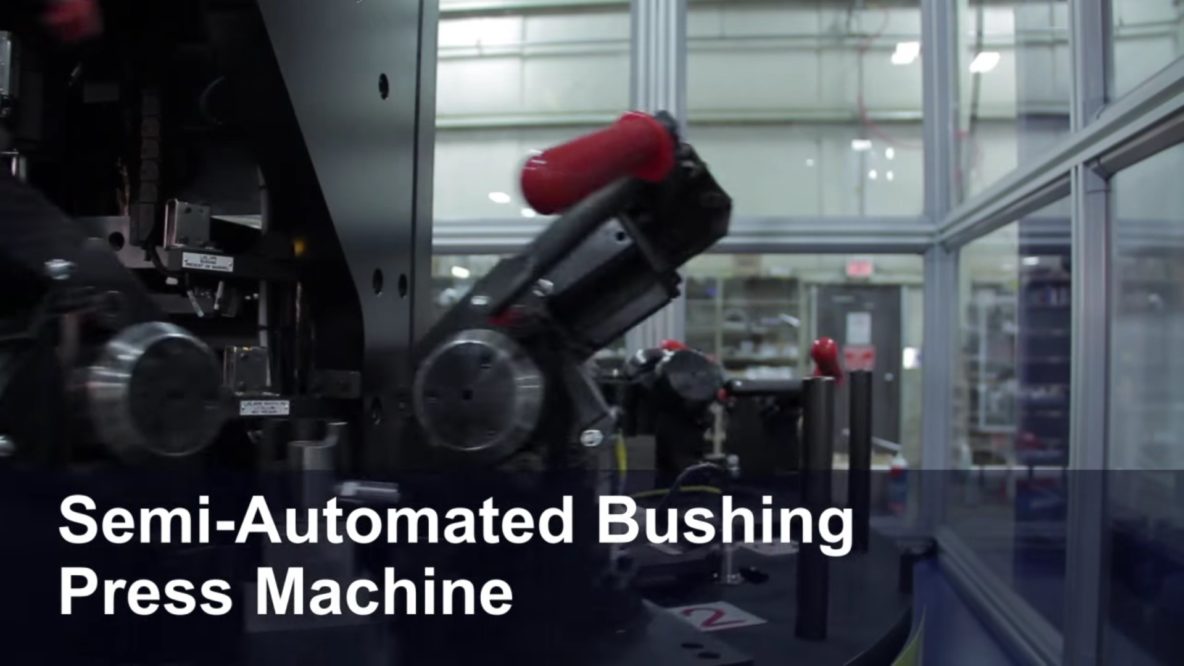

Case Study: Building a Semi-automated Bushing Press Machine to Keep Manufacturing Rolling

Sometimes a company comes to Ahaus with a specific production need and an idea of how to address it. Ahaus steps in to turn those ideas into automated or semi-automated cells that resolve the manufacturing … Read More

The Skilled Worker Void: Thoughts on the State of the Manufacturing Industry From an Ahaus Veteran

Despite the rise in technological innovations and the introduction of accessible computers and the Internet in the workplace, the manufacturing industry continues to be an integral part of the U.S. economy. But for the past … Read More

The Shovel: Thoughts from Rick Ahaus, Chairman of the Board

As I sit in my office, I notice standing in the corner, a shovel. One must wonder what a shovel is doing in a neatly organized office (thanks to Wanda) that I’ve inhabited now for … Read More

Employee Profile: Ahaus Controls Engineer Kevin Tilton

Kevin Tilton, controls engineer at Ahaus, has been with the company since 1992. Tilton performs an extremely important function of our machine building process: he designs the electrical interfaces and mechanical controls that human operators … Read More

Workholding and the Challenges of Device Design for the Medical Industry

Ahaus’ products and services are increasingly being applied to the challenges of designing for the medical industry, which continues to thrive and grow on an exponential scale due to the constant rise in innovations and … Read More

The Ahaus Apprenticeship Program — Thoughts from the Coordinator

The Ahaus Apprenticeship Program is a nationally accredited education program for toolmakers and CNC machinists. We’ve been offering the program for more than 30 years, because we believe training and development, as well as a … Read More

The Importance of Workholding, and Looking to the Future

Whether cut, drilled, shaped or machined, the goal of any manufacturing process is to produce consistently precise products. An unquestionably important but relatively unacknowledged aspect of the manufacturing process is the workholding fixtures used to … Read More

The Ahaus Apprenticeship Program From the Perspective of a Student

Good employees are the backbone of any successful company. But finding dedicated workers who are ethical, well trained and efficient can be a challenge. There’s a growing myth that an employer should wait for potential … Read More

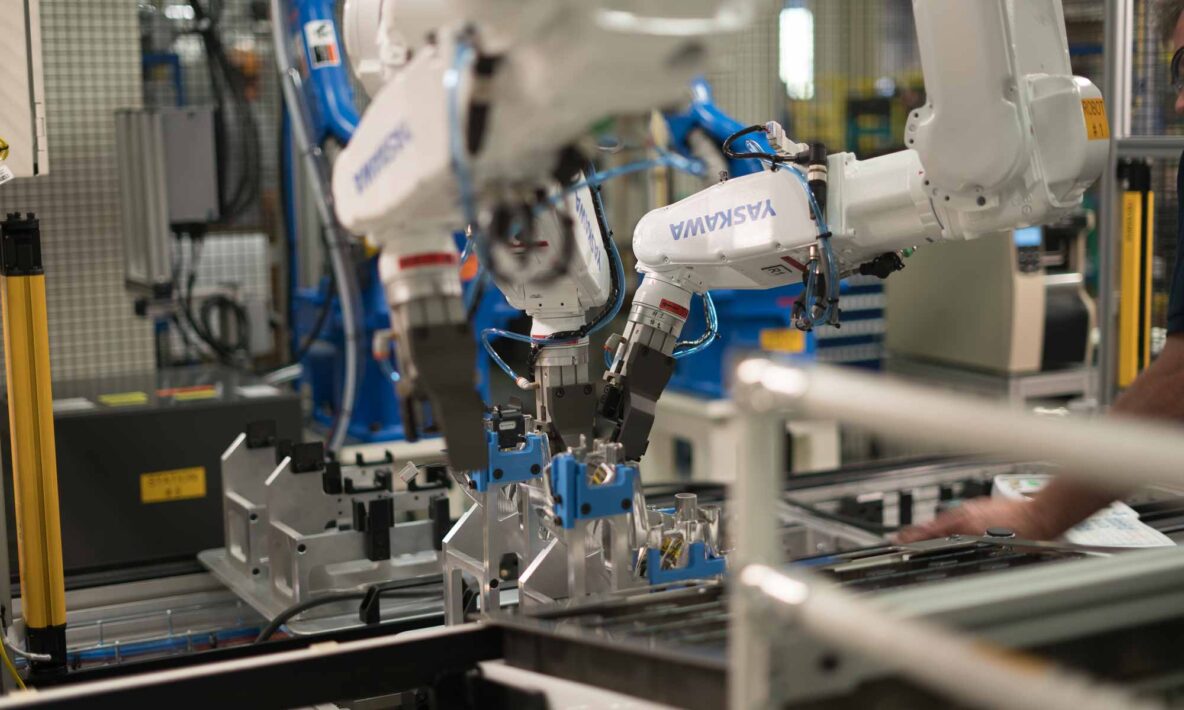

Robot Integration

Since the first robotic arms began to appear on assembly lines, concerns have rippled throughout the workforce in regard to robots one day taking the place of human workers on a large scale. Thankfully, we … Read More

Hydraulic Vise Designs: Whatever the Application Requires

Workholding is an essential yet relatively unsung aspect of any manufacturing or machining operation. Regardless of the production requirements of a workpiece, workholding fixtures will very likely play a critical role in its processing. Whether … Read More

Radiator Assembly Incorporates both Automated and Manual Methods

An automotive radiator is basically a heat exchanger designed to prevent an engine from overheating. The liquid coolant that is circulated throughout an engine becomes extremely hot and requires cooling before it is distributed back … Read More

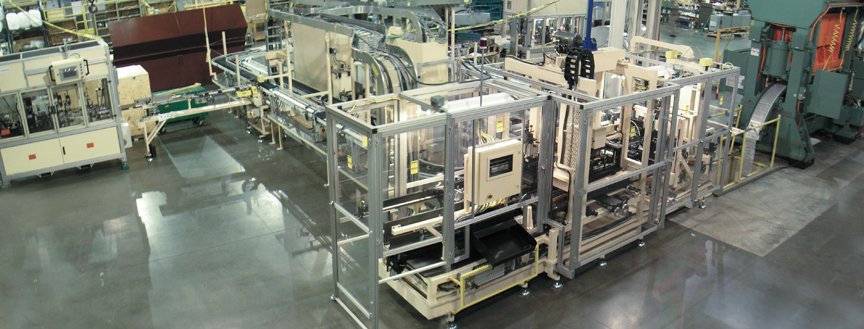

Assembly Equipment and Methods Modernized for Ease, Consistency

We’ve come quite a long way since Henry Ford first introduced the assembly line in the early part of the 20th century. Even in their wildest dreams, Mr. Ford and his counterparts would have found … Read More